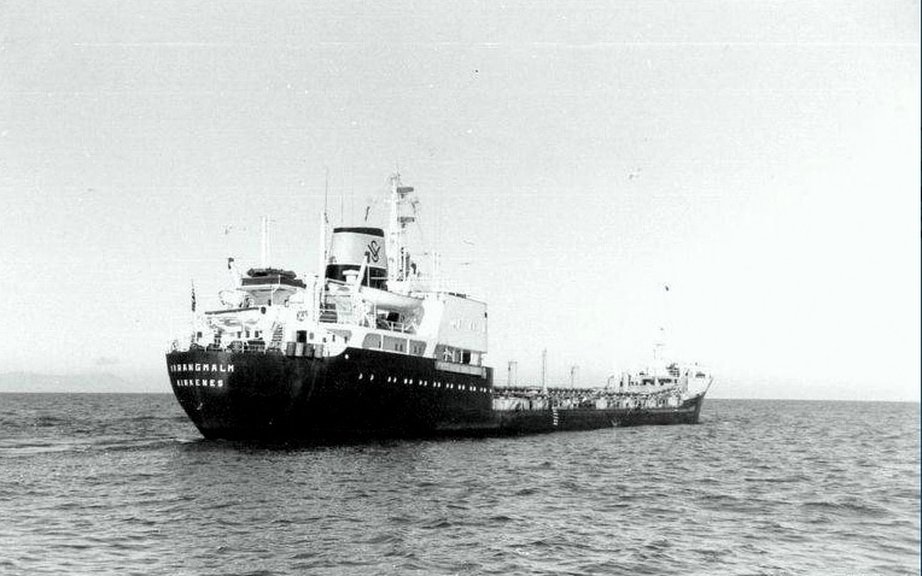

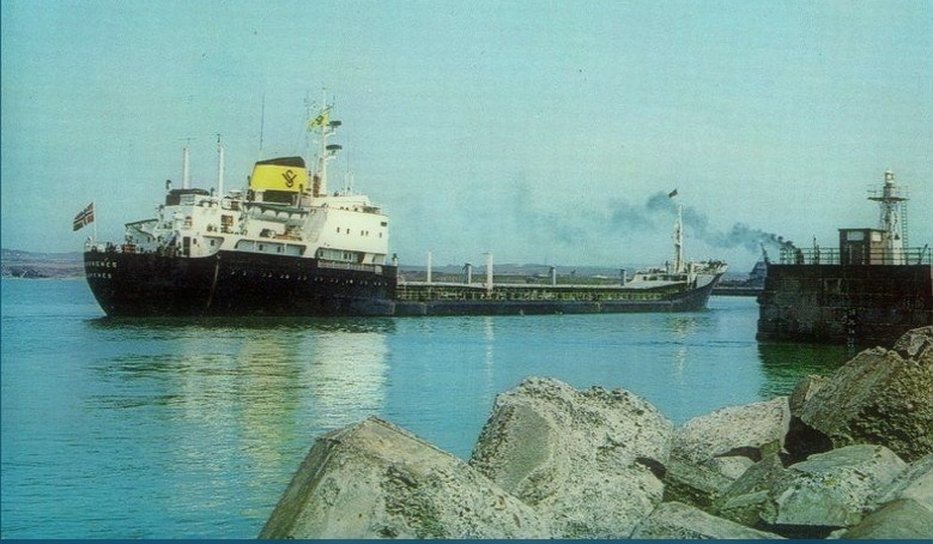

The period from c1950 to the early 1970's was a boom time for the Port of Workington with the local steelworks struggling to keep up with demand for their world famous rail track and other products. This required a vast amount of raw iron ore, which was shipped into the port from places like Scandanavia, South Africa and Spain by large bulk carrier ships. The Norwegian company "Sydvaranger" had three ships running a regular shuttle service from the ore mines in Kirkenes and Workington.

Varangmalm

Varangberg

Varangnes

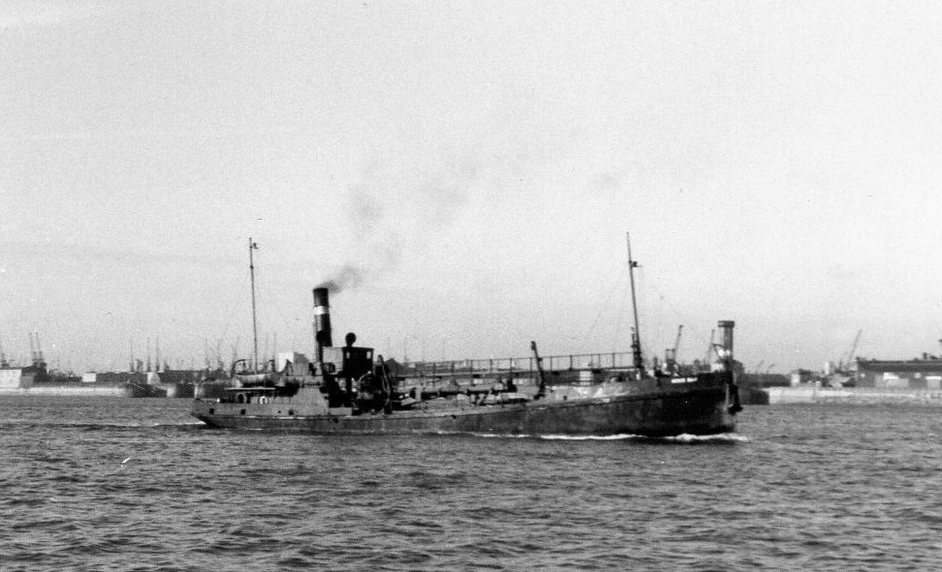

To keep this continuous armada of ore carriers docking safely, the Workington Harbour & Dock Board had their own "floating plant" consisting of the bucket dredger "Cocur", two hoppers, "Mossbay" & "Oldside" to dispose of the dredged up silt, and a steam tug, "Solway" (pictured below) to assist the carriers to dock.

I worked on the "Solway" for three years and it was a great job, my only regret was not taking more photographs!

"Solway" formerly "Empire Ann" was built for Townsend Ferries in 1943 and was sold to United Steel Companies in 1948. She was sold on in 1975 with the collapse of the steel making industry and eventually scrapped at Fleetwood by Meyer Newman in 1977.

I worked on the "Solway" for three years and it was a great job, my only regret was not taking more photographs!

"Solway" formerly "Empire Ann" was built for Townsend Ferries in 1943 and was sold to United Steel Companies in 1948. She was sold on in 1975 with the collapse of the steel making industry and eventually scrapped at Fleetwood by Meyer Newman in 1977.

Solway

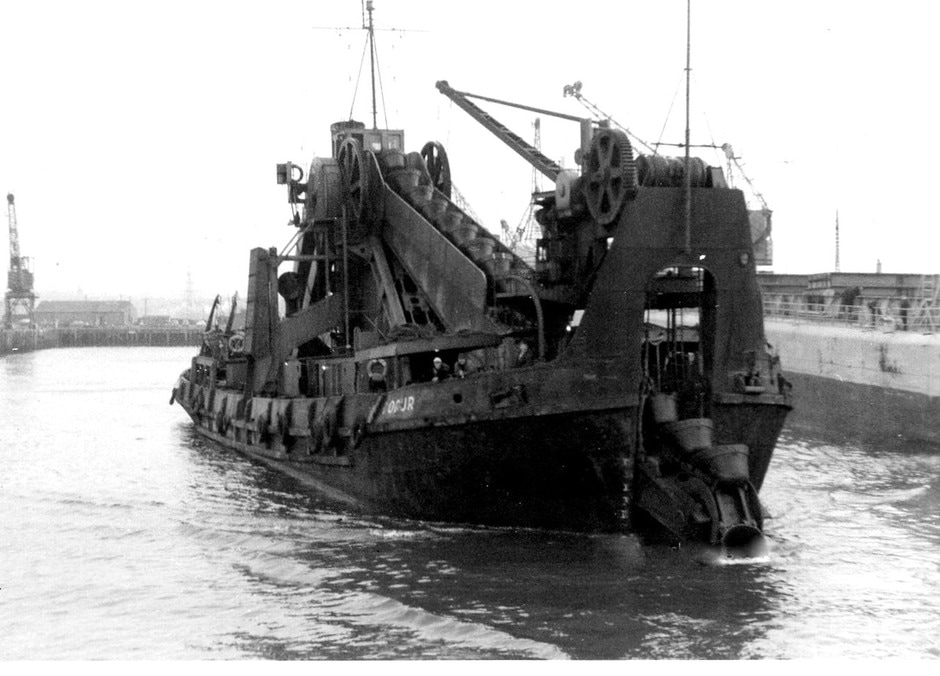

The "Cocur" was built for Workington in 1949 by Fleming & Ferguson on the River Clyde. She was replaced by contract dredgers when the vessel was in need of upgrading and to lower costs. Sold in 1972 and renamed "Vittoria" she was eventually broken up in 1983.

Cocur

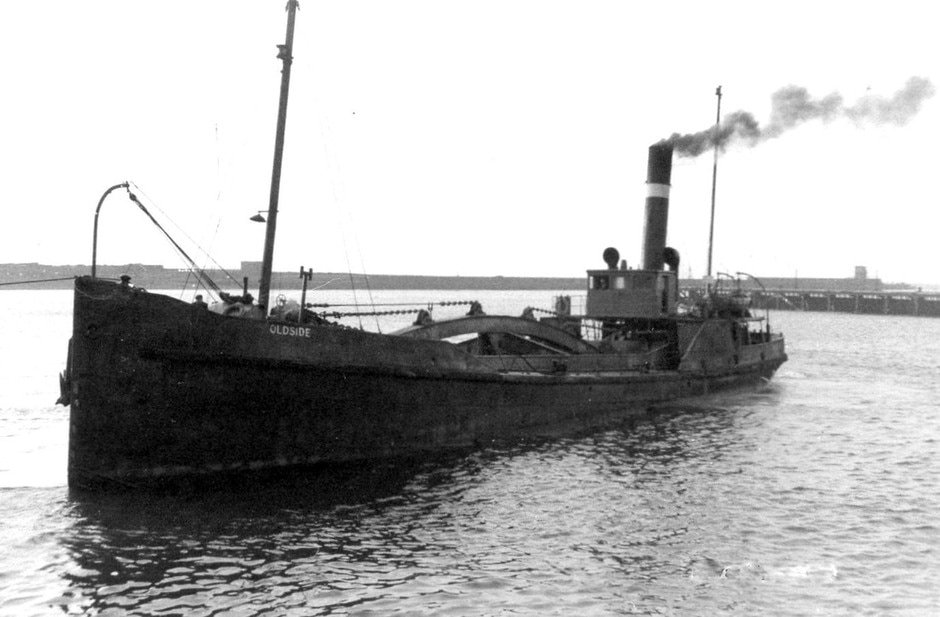

"Oldside" was built in 1908 by CH Walker. She was 172 feet in length and 436 grt. and was coal powered, the only "mod cons" on the bridge were a compass and a steering wheel!

She had been laid up for quite a while but it was decided to use the tug crew, who were also in a quiet period, to man her up so that they could utilise both hoppers with the dredger. Having not been used for sometime the mate instructed me to take an oil can and "oil everything that's rusty" -which i did. So off we went to collect our first load to dump a few miles out in the Solway Firth on the waste grounds. The release mechanism was activated and the doors in the bottom of the hold opened and the silt dropped onto the seabed...so far so good!

A large circular metal disc then had to be tightened against another one which provided the grip and the means to re-close the doors, well that was the plan, unfortunately, an inexperienced hand in these matters, had oiled the friction plates because they were rusty! It was the mates fault entirely I reckon but it only took a hour or so to clean off all the oil and everything was fine.

She had been laid up for quite a while but it was decided to use the tug crew, who were also in a quiet period, to man her up so that they could utilise both hoppers with the dredger. Having not been used for sometime the mate instructed me to take an oil can and "oil everything that's rusty" -which i did. So off we went to collect our first load to dump a few miles out in the Solway Firth on the waste grounds. The release mechanism was activated and the doors in the bottom of the hold opened and the silt dropped onto the seabed...so far so good!

A large circular metal disc then had to be tightened against another one which provided the grip and the means to re-close the doors, well that was the plan, unfortunately, an inexperienced hand in these matters, had oiled the friction plates because they were rusty! It was the mates fault entirely I reckon but it only took a hour or so to clean off all the oil and everything was fine.

Oldside

The last member of the fleet, and the oldest, was "Mossbay" She was built in 1901 and similar to "Oldside" at 172' in length and was also built by CH Walker. She is pictured here on the River Mersey c.1969. All the vessels required drydocking on the Mersey for hull inspections etc so it was decided the "Cocur" would be towed by the "Solway" and the two hoppers could steam down on their own after taking on extra supplies of coal for the journey.

It was an uneventful voyage apart from when we started to pass the Eskmeals gun range south of St. Bees Head as splashes started to appear in the sea a few miles ahead of us!

We, on the "Solway" went into Cammel Lairds, Monks Ferry No. 1 drydock for several days while work got underway. The mate and myself spent many happy hours walking around the docks in Birkenhead looking at the scores of ships from all over the world busily loading or unloading their cargoes.

It was an uneventful voyage apart from when we started to pass the Eskmeals gun range south of St. Bees Head as splashes started to appear in the sea a few miles ahead of us!

We, on the "Solway" went into Cammel Lairds, Monks Ferry No. 1 drydock for several days while work got underway. The mate and myself spent many happy hours walking around the docks in Birkenhead looking at the scores of ships from all over the world busily loading or unloading their cargoes.

Mossbay

The pilot boat in use at the time was "Cumbria" which I spent 18 months working on. It was a hard working and reliable boat that covered Workington and Silloth and also Whitehaven until they acquired their own boat "JT Pears" She was a boat that could be heard more than seen as there was no silencer on the engine exhaust!

Cumbria

A sad view taken in 1972 of the "Oldside" under tow on her way to the breakers yard in Barrow in Furness

Ore carrier "Phillippe LD" a regular visitor, pictured here docking with the assistance of "Solway" and Clyde Shippings tug "Flying Mist" on the bow.

Such was the demand for ore to produce the steel products the port of Workington was regularly congested with ships, the problem with that was, as the height of the tide works in cycles, rising and falling with the influence of the moon, so the there could be less water held in the dock as time progressed with the danger that the carriers waiting to be unloaded could actually go aground. The solution was to shuffle the ships around and unload part of their cargo, so reducing the draught (depth) and alleviating the risk of grounding. This in itself caused more delays and congestion, so finally the answer was to leave arriving ships at anchor outside of the port until a berth was available.